Sustainable building data - 2050 Materials

Welcome to episode 61 of the green & healthy places podcast in which we explore the themes of wellbeing and sustainability in real estate and hospitality.

Phanos Hadjikyriakou is co-founder and Ceo of 2050 materials, an online database of sustainable building products and intelligent tools that help architects and designers in their efforts to create low-carbon, circular buildings and interiors.

In this podcast we discuss the genesis of the company, the unmet need it addresses in real estate and the sustainability problems it tries to solve, such as toxic building materials and those that are especially damaging to the environment when viewed from a Life Cycle perspective, considering its extraction, use phase and disposal options at its end of life.

We also cover some of the many sustainable building material certification systems as well as how Artificial Intelligence could start to leverage this type of database to propose sustainable, healthy solutions to architects and designers in the not too distant future.

Check out 2050-materials.com while you’re listening along!

FULL TRANSCRIPT FOLLOWS COURTESY OF OTTER.AI - EXCUSE TYPOS!

Matt Morley

First of all, thank you for making the time to join us today on the podcast. Pleasure to have you here.

Why don’t we talk about the genesis of the business? So how did 2050 materials start as an idea? And what’s that journey been like, from the initial concept through to where you’re at today?

Data on Real Estate Supply Chains

Phanos Hadjikyriakou

Yeah, great. So I guess that goes back a little bit to my background. I’m an engineer by training. And I would say I’m pretty much a data person in my brain, I was working basically in the financial sector, helping investors align their portfolios with different climate strategies, and essentially giving them different kinds of data on climate change risk.

2025 Materials Principle

The whole idea behind 2050 Materials started when I was working with a few very large real estate investors who started talking about supply chains and supply chain emissions and embodied carbon in the portfolios and in the buildings they owned. I come from a family of architects and people working in materials distribution.

So that sparked my interest, what I figured out very quickly is that what investors were starting to ask for and talk about, everything related to supply chain and material impact, is something that the people on the ground, the designers, the contractors, the building materials suppliers, simply did not have the right data to deliver on sustainability performance.

So I thought that, first of all it’s a big problem, secondly, it’s a big opportunity to fill that gap with a solution. I generally have an affinity for innovation within the material sector. I just think it’s very cool when you see a new material that you can actually touch and feel. And there’s a story behind where it comes from and what it’s been made of. And also if you can add the impact data to it. And that, for me makes it very interesting.

Much More than a Sustainable Building Materials listing Site

Matt Morley

So let’s look at that. Because obviously, on one level, what you’ve developed is, if you like a database of materials, that for someone like me, who’s involved in real estate, primarily interiors, less the construction side, there’s a constant search for new innovative materials that not only look good and fit into a particular space that we’re trying to propose to a developer, but also that are doing some good or and certainly doing less harm to the environment.

Then there’s another level to all of this, from what I can see, it’s a bit more than just becoming an online collection of materials, right, there’s more depth to it that I think is really where it starts getting interesting. Can you talk to us about those calculations and about that extra level of detail that you’re able to get into around the body carbon and the impact of the materials? The platform provides simplified metrics to help designers quickly assess the impact of materials.

Moving to a Low Carbon Construction Industry

Phanos Hadjikyriakou

Well, let’s start from the assumption that we need to transition to a low carbon economy and to Climate Neutral economy. And the construction sector, whether you’re an interior designer, or an architect, or just work in the built environment, the impact your work has is actually massive. And our thesis is that data is the key to getting to a stage where we are designing and eventually building buildings in line with the climate emergency.

Now, the interesting thing about this space is that there’s an abundance of data that shows impacts of specific products and materials in the sector. The problem is that that kind of data is all around the internet, usually in PDFs, and usually in a format that’s very technical. So it’s usually what’s called the lifecycle assessment or an environmental product declaration that states these kinds of values.

Unfortunately, the assessment and the output of these reports are meant to be read by a specialist in the sector. And what the reality is, you need designers and architects who are not specialists in the sectors to still be able to access and understand that data.

So something that’s often, let’s say, misconception of a lot of people when they land on our platform, is that we do a lot of assessment of existing product. In fact, all we do at this point is gather existing data from different sites, we digitize it so that it’s actually accessible on the platform. And you don’t have to look through 1000s of PDF files to extract the information you need.

And then finally, we, and probably most importantly, we actually simplified to the extent that it keeps its accuracy, but it’s actually understandable by a non specialists. So what that means is that we filter out the detail that is probably unnecessary to most designers and architects, so that we quickly give them the numbers they need in order to make an assessment. And we put that at the forefront of the platform, providing easy to consume data on the sustainability performance of building products.

3rd Party Certifications for Sustainable Materials

Matt Morley

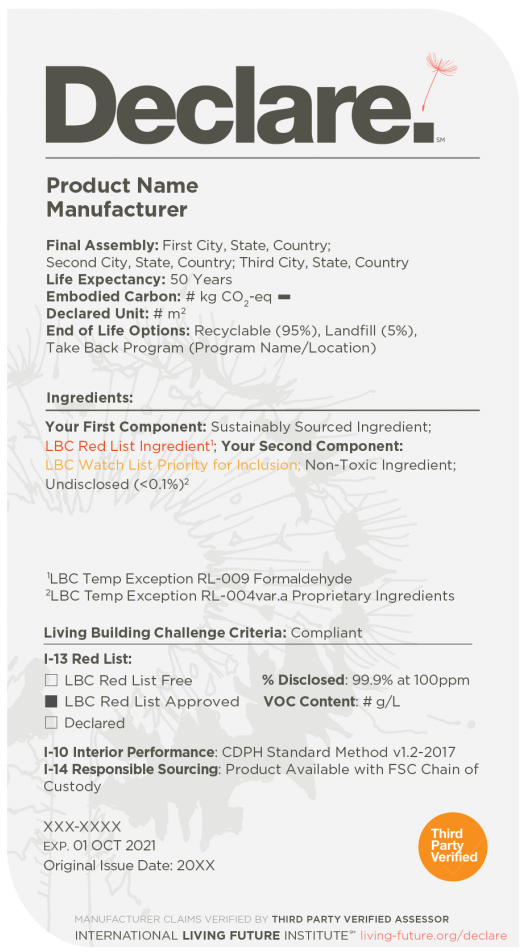

Just as a note, I would say I’m totally on board with that approach. I think there’s absolutely no issues in relying on established third party certification systems, whether it’s an environmental product declaration, or a healthy product declaration, or something like that, declare a red list to the cradle the cradle, for example, those are the gold standards, and when you have a little bit of knowledge about this space, then I think you can leverage that, you’re standing on their shoulders.

Phanos Hadjikyriakou

Yeah, absolutely. I mean, what we always say is that we are trying to democratize these kinds of sustainability assessments, and that exactly pointing to the fact that yes, we do have Sustainability Consultants and specialists using the platform. But what we are building the platform for, or the person, or the stakeholder we’re building the platform for is actually the average designer, architect, contractor, who is having conversations with a customer or with a colleague around sustainability.

They need to start understanding this kind of data without going back to university and getting a degree in this. The platform is built for designers and architects to use data during the design and specification phases, simplifying metrics for easy understanding and use in this context.

The Evolution of Sustainability Data on Sustainable Building Materials

Matt Morley

It's interesting, if you tried to do this, five years ago, 10 years ago, you probably wouldn't have had quite so many materials, right? So it's a sign of where the industry is at now that you're able to have such a wide collection, I think it's, it's the right time, because it is now becoming the choices quite expensive. And it's becoming actually sometimes harder to filter through that. But why don't we take a step back?

I understand that perhaps not everyone may not understand the context, which is that there are unhealthy versions or unsustainable materials going into our built environment, both from the construction and then the interior fit out.

So from your perspective on the inside of this industry, like what are the main dangers there? And what are what are we? What are you battling against presenting these more sustainable healthy materials? And what's the problem here with the unhealthy buildings?

Phanos Hadjikyriakou

That's an interesting question. So I would say, let's look at human health. First, when it comes to coming into contact with harmful substances and pollutants, we actually come into contact with those in our daily lives more frequently than we realize. So that might be from building insulation that's, that's packed with flame retardants, to chemicals in our food packaging, in might be wet paint that's emitting VOCs, volatile organic compounds.

So all of these things actually contribute or can contribute negatively to human health and cause things like asthma and a bunch of other health issues. There's definitely there's definitely, let's say, a very imminent health issue that is fixed when you start looking at more sustainable products. But I would say that a big driver of health is also just global health and looking at climate climate issues.

I would say that, yes, in the short term, we want to avoid, for example, vocs emissions in our buildings, because we, we don't want to have respiratory diseases in the long term. And it's not even that long term. If we don't stop emitting as much carbon from the construction industry, then we all of our lives, I believe will be impacted from climate impact. I would split the two things into let's say, direct human health today and then long term health for us. For our kids for, for basically everyone who is living.

Matt Morley

Well “green and healthy places” is the name of the podcast. I think that connection between green as in good for the planet, and healthy, good for us, or in this case, good for the people spending time in a space, then the yin and the yang interact, I think is fundamental.

Do you think there's, is there an element of perhaps sustainability being more applicable to the building materials themselves? Just in terms of the quantities involved for concrete and steel, for example, versus say the interior fit out? Where perhaps it's more to do with health? Or is that is that dichotomy to generalist?

Environmental Impact of a Building Over its Whole Lifespan

Phanos Hadjikyriakou

I think traditionally, you know, I think concrete and steel is obviously the two materials that kind of get the spotlight, especially when we're talking about carbon emissions. And that's because the industry as a whole is producing a lot of carbon emissions. So if you look at a building, it's an interesting case study, actually, because if you look at the buildings materials, you would see that yes, most of the carbon emissions of a new building is in the foundation and the frame. So usually carbon, usually concrete, and steel and aluminium.

Unfortunately, if you actually look at a specific time span, let's say 50 years of a commercial building that hosts officers, say in central London, the reality is that the fit out the change of fitouts. And the frequency of change of fitouts, actually can cause up to four times the emissions of the of the envelope of the building.

So if you take, for example, an office in central London that has new desks, new chairs, new cabinets, new flooring every, let's say, two to six years, which is the average time of fatal change, then all of those emissions related to the products and the materials that go into the, the interiors are actually much larger than the building itself. And of course, all of this has, has a certain assumption. So if we were to reuse a lot of those products, then of course, we would reduce the impact.

But as it stands today, where most of those things are either thrown in the landfill, or let's say down cycled over big extent, fitouts are massively important. So I know it's not an extremely helpful answer, because it might, it would be nicer if we could focus on a couple of a couple of sectors.

But I think what this kind of research is starting to show is, truly, if you work in the built environment, whether you are doing fitouts, or interior design or residential project, or you're a structural engineer, or anything else, your work really matters, like it really matters to be able to have access to this kind of information and to do your part in reducing emissions.

Value and Purpose in Prioritizing Sustainable Building Materials

Matt Morley

I find at some point, it becomes more about your values, or the values of your business and what you're trying to do in your work that pushes one designer or someone working in this space to consider both equally. And sometimes there are decisions to be made. And you know, what materials are better for the planet and not quite so good for their human health or vice versa? It can often be quite complicated.

I think that's why platforms and software such as what you've developed is, is important so that at the next level of detail, then when we're actually on the website looking into some of these materials, doing our research, how are you helping users to kind of make some calculations beyond just Oh, that's a green certified material, but then in terms of its actual impact once it's applied, in terms of the quantities and the scale, and where it's coming from.

So in terms of those details, is there a way you're able to help your users to factor those into the into the equation?

Circular Economy Design Metrics in Building Materials

Phanos Hadjikyriakou

Yeah, absolutely. And your question comes at a good timing, because we’ve launched the tool to do a lot of the things you just mentioned very recently, and users can trial it and try it out for free to start with, essentially what this tool allows you to do is get anything that you would find on the library and make a list of it.

And this can be done at any stage of the design process or it can be done really early stage where you’re not really thinking yet about designs and quantities and you just want to understand more or less what it means, what are the forecasted footprint of my building with me.

Once you have a bill of quantities and you really have a data list of everything you’re about to procure. What we are doing is we collect the data of the products that are on the library within this tool once you’ve selected it as a user.

We show, of course, the total carbon footprint, as well as some numbers, like the embodied carbon per meter squared of gross internal area and do some comparisons of that number to industry benchmark as well as some of the recommended numbers in the industry, we actually go a step beyond just focusing on carbon, we calculate currently a couple of circularity metrics, like the weight of the recycled content in the products that you’re selecting.

And the recyclable contents are kind of how much of the products and the materials that you’re specifying may actually be possible to recycle or reuse at the end of life. And I guess, one thing that that became important when we’re developing this tool, with a few large offices is we we initially were thinking that designers will use this tool solely based on actual products that are available in the market.

So meaning, you know, x brick by this kind of supplier or this kind of manufacturer, what we’ve developed now is we’ve developed an extra layer where it’s generic data for a specific type of product or type of material.

So something that says, for example, a clay brick from the UK without necessarily specifying who the manufacturer is. So that kind of gives a workflow that allows you to, if you’re starting by just considering materials in the beginning, you can choose your materials. And then once you get into the specification process, or if you want to see whether there is an applicable product in your area, to actually go into the product selection process during the specification phases.

Yeah, and one thing I did not mention, but you did actually in your question is, of course, the impacts that we show, you know, they show the manufacturing emissions of the product. So what’s in lifecycle assessment terms is called the A 123 lifecycle stages. But the interesting thing about setting a platform like the one we have is, we have the project location.

And we have the manufacturing location of each of those products in the library, which means that we can quite accurately calculate what the estimated carbon emissions are of transporting those materials.

So one of the things that you can do in the tool is you can pick a bunch of products from the, from the platform that are, let’s say, from China, or a London project, and you’ll see in the breakdown of emissions per category, that the transportation emissions exceed everything else, versus selecting local materials.

And I think there’s an interesting opportunity there to see, you know, what kind of products maybe does make sense to ship from a little bit further away, even though they might not be available locally versus other ones, which, of course, would outweigh the benefits.

Matt Morley

For anyone who’s done a project before with a sustainability or a healthy materials component to it. The reality is this type of detailed conversation, almost every material and it becomes a major headache pretty quickly, you’re constantly evaluating or trying to get to this type of information about not just where materials from how it was produced the impact of extracting it, and its raw format, then in terms of the manufacturing, production, then the transport, and its end of life, as well as it’s in use phase.

And combining all of that is really complicated, because it’s just, you’re trying to move fast, you’ve got climate pressure. And so I think for anyone who’s perhaps, you know, feeling frustrated or overwhelmed by this amount of information in its platforms like this, like your library that help ease that pain, and I think that’s what I what I see here, which is, it’s very easy to be drowned in the information.

We need to make decisions as quickly as possible once the project starts, there’s just no, there’s no time to lose. And I think you’re helping to smooth out that process. That’s really where I see that the sort of main benefit in terms of using this. So once you’re, once you’re building into the library, like what process are you using to screen or to filter materials?

What are you looking for as a sort of, oh, that’s suitable or that’s not suitable? Have you got your own internal benchmarks in terms of where you do or don’t accept the material?

Sustainability Standards for Materials on the Platform

Phanos Hadjikyriakou

That's a really interesting question. So first of all, I guess we live in a constant state of research within 2050. So we are always on the lookout for new new products, new materials, especially when they come from smaller companies that are just popping up whether it's a startup or a company that's been operating for a few years and we just have not seen it before.

But having said that, there is a very important point to be made about how we work. So we do not police what kind of product or manufacturer makes it on the platform, we actually want to have as many products as possible appearing there and we don't have a specific requirements for products to get on the platform, what we enforce as a library is that there needs to be some level of documentation that provides transparency on the impact of the product.

So, if you go to a library, you can look up concrete and you will find very heavily emitting concrete products and concrete manufacturers, we want to have these products, we understand the sector, at least for now still needs a lot of these products, what we ensure is we essentially put transparency over some some abstract assessment of what is a sustainable material or not, because there are no sustainable materials, in my opinion, there are materials that are suitable and can generate the Sustainable Design and there are materials that are non suitable, and the specific data related to each material does not necessarily give the answer to that.

So in short, anything can land on the platform, what we ensure when we onboard the product is that there is some level of transparency related to the impact of the material or the product is causing.

Matt Morley

Sounds like a very pragmatic and practical approach. So some degree of thinking on the part of the user is still recommended, you know, we're still going through that mental process of, of evaluating and arbitrage right, trying to decide which which one is the best in this case, and it may not be the most sustainable, as you said.

Phanos Hadjikyriakou

Yeah, I guess that's, that's one of the things that initially, you know, you start and you are very ambitious, that you will give the perfect answer to everyone and point them to exactly the one thing and they don't have to spend any time thinking. Quite honestly, we very early this very early on, we decided, you know, the specialists are the designers, they are the architects, they know how to do the research to find the right kind of product or material.

So we are not trying to replace their their specialization and the work they know how to do, what we're trying to do is replace a process that would currently take something close to three or four or five hours to compare a few products to something they can do with essentially 10 clicks within two minutes.

Matt Morley

What is the business model going forward? Is it going to eventually be some kind of a paywall so that you pay for access to the materials or the materials suppliers, manufacturers paying to be listed? How do you how do you set things up from a commercial perspective?

Phanos Hadjikyriakou

Yeah, so from a commercial perspective, we essentially list the way that we list products is is an important point as well. So we partner with essentially every certification body that is out there that certifies building material products, and furniture and all of that. And we on board the basic data that the certification bodies have.

So out of so we populate the platform, even without charging anyone really. So it's free for designers, it's free for suppliers. We currently do charge and work with suppliers when they want to have access to those pages, to enhance them to add data sheets to add better pictures to add more technical information that would help a designer actually finalize a specification or a procurement decision.

So that's currently how we work. On the project side of things, as I mentioned the beginning, there's a couple of projects that you can create as a user for free now, but that's going forward something that we would like to charge on a per project basis, obviously, as clients or regulators demand these kind of reports.

Evolving the Sustainable Materials Industry in Future

Matt Morley

That makes sense. Okay, and looking forward them to the next, say, five to 10 years. Where are you seeing this industry around healthy and sustainable materials evolving? Like what are the main sort of trends that you can see taking place that you expect to continue over the next five years or so?

A Data Driven Approach to a Climate Neutral Construction Industry

Phanos Hadjikyriakou

Yeah, so I've said this a couple of times. I think, for us, you know, the key to moving towards the direction of Climate Neutral construction sector and design sector is the data. And that's why we've had so much focus on the data. I mean, moving forward, I think what's really interesting about data is we are starting to have some pretty amazing stuff that's happening on on the AI front and on the generative design front.

I think that more and more, we're starting to see solutions that can make suggestions and generate designs for architects and for interior designers that would allow them to meet certain goals. And again, I don't think we'll, we I, I don't see a scenario where architects are no longer needed or anything like that. I think this kind of doomsday thinking is really not something I agree with.

What I see is similar to all of the hype that's happening right now with Chat GPT, where you ask it questions, and you can have it give you a lot of suggestions, an architect can have very specific tools where they say, I'm trying to achieve a net zero building in central London for this kind of client, and it needs these XYZ specifications. And then a tool would be able to give you five different scenarios of designs, material products, that would actually allow you to get there.

Then again, it's up to you as a designer, or as a specialist to kind of do the next step and, and move from there. So I personally think that data alongside the whole AI revolution that's happening right now is going to open, amazing doors and something that to the mission that we have as 2050 of democratizing these kinds of assessments and understanding very much contributes to

Matt Morley

Yeah, that's a big idea. I like that one. And in terms of how the business evolves over the next 12 months, 24 months, like, what's the as an additional functionality expanding the, the depth and breadth of the library materials? And what are you working on this next year?

Phanos Hadjikyriakou

Yeah, so we have, we are constantly working on onboarding more products. So currently, we are testing a very big push, which will expand your database to include almost every product that has an EPD globally. So that kind of does a big jump from around 4000 products to something like 50,000 products. So from a library perspective, we expect to have something in the next couple of months that is much more complete and uncover actually a lot more markets and the UK, which we've been focusing on.

On the product development side, we have some really exciting features and product pipeline around the projects tool. So currently, you're able to select you know, individual materials and make a list of your, of your materials that make up your projects. We're very much moving towards the direction of allowing, allowing people to create assemblies and see within a specific assembly what is best, and then allow them also to have some functionality of of saving their own assemblies.

Because a lot of designers architects, they reuse a lot of the designs they've done.

So our goal is to move towards a direction where you can actually start building your internal library of systems and assemblies that you're able to very quickly build projects with and also get quick assessments.

Matt Morley

Fascinating. sounds really interesting. Well, I'll be I'll be very happy to watch as you evolve over the next year, and hopefully, five or 10 years is growing the business. So listen, thanks so much for your time. Where can people find out more about the business where you what social media you engaging with at the moment?

Phanos Hadjikyriakou

Yeah, I think thanks a lot. Also for the time, people can just search for 20 Quickly materials on Google on LinkedIn. We're very active on LinkedIn, with content and educational articles and all of that stuff. And then the platform is is easily accessible and free on https://app.2050-materials.com/

Health risks of toxic chemicals and materials in building interiors

What are the health risks of toxic building materials and products in interiors? Biofilico healthy building consultants answer this and more - covering Red Lists, the sources of toxins in interiors, healthy building standard guidance on avoiding toxic materials as well as links to our healthy building materials guide. Read on for more info!

a short history of building materials

In the past, human shelter and the earliest buildings were simply made from naturally occurring materials such as clay, wood, or stone, organically sourced and all safe enough to go back into the ground at their end of life.

It was only the industrial revolution starting in the second half of the 18th century and the concomitant explosion in synthetic compounds - that in turn began to find their way into building materials - that the buildings designed to protect us from the elements around us first become a health risk in themselves (who knew!).

Slowly and almost imperceptibly, the toxicity levels in buildings and interiors continued to rise as the decades passed and the ‘chemical revolution’ proposed ever greater numbers of solutions for the construction industry… until we finally began to take defensive action in the 1970s - starting with lead!

Today, building and interior materials have the potential to negatively impact human health and wellbeing if they are not properly chosen, installed, and maintained.

These risks can vary according to the life phase of a chosen building material but we recommend taking into consideration all phases of the material’s life for good measure.

To do so, we apply the concept of a Life Cycle Assessment to better track, moderate, and eliminate harmful toxicity from a construction and fit-out project wherever possible.

It is also worth noting that if the whole cycle of a material is taken into consideration, the groups at risk of exposure to such toxic materials expand beyond just the building occupants.

The negative health effects of toxic materials have the potential to extend to those living near the factories where the materials are made, the workers using the materials during construction of a building or interior fit-out, and even those charged with disposing or recycling the material at the end of its life.

For this reason we believe it is fundamental to understand what impact building and interior materials can have on human health.

Here we will look at common sources of toxic substances in building materials; common toxic substances we want to avoid in building materials; the health risks of human exposure to such toxicity; authoritative ‘red lists’ of these harmful chemicals in building materials and what can be taken from the materials-related content of various leading healthy building standards. Let’s get it into!

Common sources of Toxins in building materials

Toxic substances can be found in an alarming number of building materials and products from flooring to insolation, carpeting, cabinetry, paints and coatings, furniture and fabrics, all manner of adhesives and finishes.

Careful analysis of all such source materials should therefore be instilled in a project’s design phase as early on as possible to implement a green procurement policy as part of the project’s DNA.

Asbestos, VOCs (Volatile Organic Compounds), SVOCs (Semi-Volatile Organic Compounds), Lead, HFRs (Halogenated Flame Retardants), Chromate Copper Arsenate (CCA), and Phthalates are some of the most commonly occurring and detrimental building chemicals for our health.

Below we cross-reference the source with the type of toxic substance:

Insulation Materials <> Asbestos, VOCs

Paints <> Lead, VOCs

Coatings <> VOCs, Phthalates

Adhesives <> VOCs

Furniture & Fabrics (e.g. upholstery foam) <> HFRs, VOCs

Composite Wood Products <> Chromate Copper Arsenate, VOCs

Flooring Materials <> VOCs

Combustion Sources <> Lead, Particulates

Cleaning Products <> Phthalates

Common toxins to avoid in building materials and products

Humans can be introduced to these chemicals through a variety of manners such as ingestion, inhalation, hand-to-mouth ingestion, skin absorption, breastfeeding, and even placental transfer before a baby is born.

These potential avenues of human-chemical transfer from building materials are compounded when interior ventilation is poor, highlighting the increased importance of indoor air quality in the post-Covid home, workplace, gym, learning environment, etc.

‘Off-gassing’ is a common characteristic of such materials, describing the release of toxic particles into the indoor air over time, which if improperly ventilated can accumulate to unhealthy levels in building interiors.

That new car / carpet / furniture smell? That’s the first wave of off-gassing. If you can smell it, and it’s not a natural material, you’re witness to off-gassing. Best open a window!

It is essential to not only choose healthy materials and products, but to also monitor and maintain healthy indoor air quality to avoid health hazards. See our section on indoor air here.

Health Hazards of toxic building products and materials in interiors

Negative health implications arise from many building materials and products, including from legacy materials, so-called “high performing” materials, and even from operations-based sources such as chemical-based cleaning products used by facilities management in an honest attempt to make interior spaces cleaner and healthier. The irony surely cannot be lost on any of us!

Although several legacy chemicals that were widely used in the past without proper understanding are now widely banned, many are still present in buildings and therefore remain a threat.

These chemicals include asbestos, lead, Chromate Copper Arsenate, and countless others yet legislation moves at such a slow pace compared to the release of new chemical compounds that we as healthy building consultants have to adopt our own strategies to help rather than relying on industry-wide legislation from above.

Asbestos is responsible for over 200,000 deaths each year, the leading cause of mesothelioma, and is a known toxin and carcinogen.

Lead is an endocrine disruptor (or ‘hormone disruptor’) and can therefore affect reproductive systems, puberty, and child development during pregnancy. Lead can be ingested, absorbed, or inhaled and upon accumulation in the body causes highly detrimental health effects.

Chromate Copper Arsenate contains arsenic, which is associated with lung, bladder, skin, and liver cancer. In addition, it can be leached from wood structures into soil and expose children to contaminants, further increasing its danger.

Halogenated Flame Retardants are commonly inhaled, ingested or absorbed through skin contact and have been found to disrupt endocrine function, cause neurological damage and even cancer. They have the potential to cause long-term health effects as they accumulate in our bodies.

VOCs and SVOCs are compounds that are emitted from materials and accumulate in interiors. VOCs can cause sick building syndrome, nausea, and central nervous system damage. Gaseous at room temperature, their negative health impacts increase considerably with poor ventilation and generally low indoor air quality. These compounds are commonly inhaled, and some VOCs are even considered carcinogens.

Phthalates are known endocrine disrupters, negatively affect reproduction and development, and are carcinogenic. Their health impacts also bioaccumulate, meaning they slowly build up over time and cause detrimental health effects.

Red List Resources of toxic chemicals in building materials

There are several resources that can provide guidance on so-called ‘red list’ materials, or materials that have scientifically proven negative health impacts and should ideally be avoided in all building projects with a view to human wellbeing in interiors.

The International Living Future Institute (ILFI) has a definitive and highly demanding material red list for example while health-oriented design practice Perkins & Will has its own precautionary list that provides information on unhealthy chemicals and materials they believe should be avoided.

Cradle 2 Cradle (C2C) sustainability certifications for a product or material can provide a resource for healthy materials.

In addition, ingredient disclosures such as Declare, and Health Product Declarations (HPDs) can help guide and inform builders and designers on making health-focused choices by encouraging transparency from manufacturers.

In sum, there is no longer any need for this to be an endless laborious task, project teams can and should leverage the work done already by standing on the shoulders of giants and implementing procurement policies that prioritize products and materials with high recycled content, HPDs, Declare labels and so on. This then places at least some of the responsibility on the general contractor to contribute to such sustainability efforts.

healthy Building Standards on materials and avoiding toxic substances

The WELL, LEED, and BREEAM certification systems as well as the Living Building Challenge provide resources and guides for healthy material implementations.

WELL, focuses on the human health implications of all building-related decisions, provides in depth research, guidelines, and strategies to avoid unhealthy products and materials within the built environment. As such it is a definitive research tool and guide for us as healthy building material consultants.

The US Green Building Council’s LEED and the UK’s BREEAM both encourage material transparency too of course, as well as encouraging healthy indoor air quality through low VOC emissions and proper ventilation.

As with so much in the world of healthy buildings and healthy interiors, the two concepts are in fact inextricably linked - enhanced indoor air quality and a healthy materials procurement policy go hand in hand.

As mentioned previously, the Living Building Challenge, part of the ILFI standard, focuses on choosing responsible materials and provides an impressively researched Red List of materials to avoid.

Contact us to discuss your healthy building materials enquiry.

Bamboo in sustainable buildings and interiors

A discussion by Matt Morley of Biofilico sustainable real estate and interiors with Manuel Diaz Cebrian, a Mexican entrepreneur promoting a vibrant new bamboo industry in his home country that comes with social impact and environmental benefits aplenty.

sustainable building materials and interiors

the case for bamboo

Welcome to episode 51 of the Green and Healthy Places podcast, in which we explore the themes of wellbeing and sustainability in real estate and interiors today.

I'm your host, Matt Morley, founder of Biofilico healthy buildings and in this episode i’m talking to my good friend Manuel Diaz Cebrian about his role in creating a new bamboo industry in Mexico.

Manuel was previously a Director at the Mexican Tourism Board in London where he managed the country’s image throughout Europe, repositioning Mexico as a cultural and culinary destination to beat.

He is now Director of Special Projects for Marbella Design Week and is launching into the world of sustainable entrepreneurship by agitating for a Mexican bamboo industry to rival that of nearby Colombia.

We discuss bamboo’s sustainability credentials, it’s various applications in sustainable buildings and interiors, its social impact benefits for indigenous peoples in Mexico, the influence of Bali’s Green School on bamboo-friendly architecture and architecture collectives around the world, and mucho mas.

Matt Morley

So you're doing really interesting work around sustainable bamboo. And it's one of those materials that has a wide understanding to some extent, but I think there's also a lot of confusion.

So why don't we start with that piece around the varieties of the bamboo as I know that it's basically a grass, but how many different varieties there are and which ones are most relevant for sustainable buildings and interiors in your opinion?

Bamboo as a sustainable building material

Manuel Diaz-Cebrian

Absolutely, I'd have to tell you, first of all, my introduction to bamboo was as a gardening ornamental plant. When I went to Bali for the first time, I was so impressed to see and stay in a hotel that was built completely of bamboo; I didn't know that sustainable bamboo had all this potential to support a structure such as a hotel building for example.

So then I came back to Europe, and especially in Mexico nobody knew that much about the potential of bamboo so I started to look at its business possibilities in Europe and North America where it is less well known.

Varieties of sustainable bamboo material

There are more than 1600 kinds of bamboo. You could imagine that the varieties will differ according to climate, to their kind of soil, altitude, etc. Every single kind of bamboo developed in different climates and characteristics of soil. But they're among these there are possibly seven used widely used in sustainable construction of buildings.

Its strength is how fast it grows, as you mentioned earlier, many people do not really understand its possibilities as a sustainable materials for interiors or buildings, OK maybe you as a healthy building consultant yes you know more than others but actually very few people know that bamboo is not a tree it is a grass.

It can grow one meter in height each week once it is 3-5 years old and it could grow up to 30 meters in height, with a width of 20cm-30cm.

Reducing the carbon footprint of buildings interiors

Matt Morley

So that brings us into the discussion around sustainability and bamboo being a fundamentally sustainable material for buildings and interiors. I know there's also some interesting information around its carbon footprint in particular, we're all I think now finally paying far more attention to the carbon footprint not just of our buildings, but also the interiors, in fact of the interior fit-out - or how much carbon are we embedding into the buildings and interiors that we're producing.

So, how does that work in terms of preventing deforestation, which I guess is to some extent explaining its advantage as a sustainable material right?

Manuel Diaz-Cebrian

So bamboo stores its own water, it’s moving up and down inside the tubes of bamboo basically, its roots are not very deep. Bamboo recovers the nutrients it needs from the soil, it is capturing carbon rather than releasing it into the atmosphere. The carbon can stay locked away for 30-40 years like that. It depends on how you use it and dispose of it.

Reducing deforestation via sustainable materials such as bamboo

Talking about deforestation, obviously no single species is a complete solution to the problem so bamboo can play a role with a multi-crop strategy to ensure biodiversity and regeneration of soil. It is less advisable to have entire jungles dedicated to bamboo alone as a mono-crop strategy.

Primarily, bamboo is going to give the soil the nutrients it needs for healthy development and regeneration. Bamboo is a tool to help us regenerate our forests in an intelligent way, it ha a role to play in that process.

I know we had to stop the forest in the forest state in our jungles and wood, but there's already a lot of plant that has been damaged. And bamboo comes as a resource to regenerate those areas that have been already destroyed.

Growing sustainable bamboo materials around the world

Matt Morley

Can bamboo only play that role in certain geographies and latitudes around the world? What are its limitations in terms of locations?

Manuel Diaz-Cebrian

It all depends on the altitude in the soil, from the climate on the humidity. Obviously the Chinese and the Asians developed it most aggressively and bamboo is a native plant from that area but it is also found in Latin America for example, as well as Indonesia of course.

In Japan, bamboo is considered a very fine material while in China it is less prestigious, almost a symbol of poverty because it was so readily available.

Now we know that sustainable bamboo can also be grown in Mexico, it’s just a matter of culture, learnign how to care for it, harvest it, treat it and turn it into sustainable building and interior products.

For example bamboo is often treated with borax to prevent bacteria killing the bamboo. It’s a successful treatment that may involve submerging the bamboo in borax for instance.

Examples of bamboo in sustainable interiors

The applications of bamboo are what we can do with it in real estate and interiors, so it can be a materials such as flooring and panels. It can be used as a tubular product for construction as in that format it has the highest capacity for being a load-bearing material in structures.

So, that gives the bamboo a certain strength, because actually in the industry of the construction or index industries, we produce them, they are the metal, tubular things because they the tubular form resist a lot of impact and way bamboo has this form and strain by nature.

And you can see this example in Bali and many in many pavilions of examples from Belize is this very well known Colombian architect, he's been actually building up pavilions and churches of bamboo in our in his natural form Joseph tubular that you will have seen and supported with engineering techniques.

uses of bamboo for architects and interior designers

Matt Morley

So you mentioned the the same tubular shape that provides inherent strength to the material. So when you in terms of those characteristics, when you're talking to architects, when you're talking to designers, what characteristics are of most relevance?

What are the things that that can ultimately make it so useful? And how is it applied in different ways not just in a tubular form but I know I've seen it come through and flooring into effectively tiles so you get into flooring tiles as an alternative to wood.

Manuel Diaz-Cebrian

The possibilities are endless! I'm gonna give you a lovely example - you could produce fabrics you could produce food, you could produce jewellery, even juices and food. So really you could use the whole thing in different ways. to produce fabric is very popular now in India, the number one country producing bamboo textiles.

Bamboo is has a great future because it's durability number one and number two the hardness and number three the rapid growth. Those three factors are the most important factors to consider all the time. It can be used in kitchens, in flooring both indoors and outdoors. Once you engineer bamboo you can create different textures, colors, and usages.

For example, there is a hotel in in the Netherlands in Amsterdam called Hotel Jakarta mainly made from bamboo combined with other woods.

Why is important for the architects or the people in the construction industry to use bamboo. Well, first of all, for the three characteristic as I mentioned earlier, there's durability, strength and agility and obviously the hardness but the other one is just to support the sustainability of this resource. The more demand, the more we can support a boom in bamboo.

What is preventing bamboo from becoming a more widely used sustainable material?

The problem we have is that people are still very non aware of the opportunity for bamboo. I’m involved in creating a network of growers of bamboo in Mexico, for example. Obviously, compared to Asia, in Latin America, the industry for bamboo is very small. But this is more because we didn't know the potential, or how amazingly profitable it could be.

Because obviously, we didn't know how to use it or what to do with it as a sustainable material. We want people to learn how to take advantage of the durability of the material and the demand for it in treated form. That is what' is missing at the moment in Mexico.

Matt Morley

So I think that's what I find so interesting about what you're working on here, this project of effectively creating or reinventing the bamboo industry for a country like Mexico. So as I see it, you've got effectively three levels, right you have the producers, you have the crops, you need the space, you need the fields, you need the farmers to produce it and look after it.

Then there's the processing / treatment piece in the middle. And then a final piece, which is around the sales and communication and the distribution of where it goes to the end consumers which we've just covered some that bit in the middle, between the growers, and those who purchase the refined product. What does that what does that look like?

Or what could that look like in Mexico who's doing that refinement of the raw material and turning it into a product? Or how could that look in a in a new industry in Mexico?

Manuel Diaz-Cebrian

Let me go back to something as important mentioned, John Hardy created the Green School, which is the School of Bamboo in Bali years ago. He fell in love with bamboo. And they discover all the boundaries of this material. And then through the years, they created the Green School of bamboo in order to educate people on its potential. So it started being a school for children, and then became a school for architects.

John's Hardy daughter is a famous architect now too, she's the one that came back to the roots of her father, now she's one of the most popular and famous architects focused on bamboo buildings construction. The Green School has educated a lot of architects worldwide.

Interestingly, these architects and their word of mouth has created a lot of small collaborative groups that are now dedicating their lives to work and teach people what to do with bamboo. why it was important to harvest to harvest it, why where you can do it, how you could go with the bamboo not necessarily being rich, but actually how do you use it.

There is a famous architect in Mexico, she is working on a program that is started in Thailand about how to build your own house using bamboo? How incredible is that - teaching people to grow bamboo and build their own house with the material they have grown.

Social impact and sustainable bamboo

One of the reasons I’m getting into the bamboo industry in Mexico is because obviously the countryside in Mexico, Latin America is kind of cool. So bamboo is certain areas that are tropical, have been achieved those, they the coffee industry, I know the industry has really damaged our jungles and on our land tremendously so integrating bamboo into the selection of natural resources that you could use in a particular habitat partially resolves that issue rather than damaging the soil further.

So the whole idea is for indigenous people get a benefit from harvesting the bamboo, make the main number more profitable. And also not only for the construction, or use it as well as decoration items, for chairs, for lamps, all the stuff in red to get the added value of the bamboo. Because not everything is used on the construction, some leftovers are thrown away. The whole idea is to teach people how to take the benefit from the whole bamboo stem.

Colombia is the most advanced country already in this industry as they started years ago but Mexico has great potential too!

How are you helping to create a sustainable bamboo industry in Mexico?

First of all, you got to create the union of producers of bamboo, because they're kind of separated at the moment, it’s all very disparate and spread out, nothing brings them together into an industry yetto unify a price point, control quality, how it is treated, promote this new sustainable building interior resource to local architects and interior designers, etc.

Matt Morley

Really appreciate how you've described that kind of playmaking role of putting it together piecing the different elements together so that you create what is hopefully going to be a long term project around a sustainable alternative to building with less and less sustainable building materials.

So I think it's got so much merit if if someone wants to read further into the subject if they want to explore the topic a bit deeper. Is there what's uh, is there a recommended resource? Or where would you say we could go to kind of learn a bit more?

Manuel Diaz-Cebrian

Well, I have to tell you actually, I've been researching bamboo, I mean, ideally, in a professional way for the last few years. Because as you know, I'm the director of special projects for Marbella Design.

We gave a talk two years ago to architects and designers in Marbella and we started educating our guests about bamboo there. Many did not know the roof of the airport terminal at Madrid Barajas is made of bamboo for example!

I'm going to Paris in two hours just to see a pavilion that Simon Velez has built made of bamboo. So it's more and more and more that you're seeing this.

Last year, I invited Dr. Pablo van der Lugt to speak at Marbella Design Week, author of the book called ‘Booming Bamboo’ that I recommend to architects and interior designers interested in sustainable interiors or building construction. This is something of a bible in fact. I give a copy to every single person I meet who wants to learn more about the wonders of bamboo!

Show notes:

Biomimicry and Biophilic Design: Biodesign Insights by Danielle Trofe - Wellness Design Consultants

Talking biodesign, biophilic design & sustainable design with Danielle Trofe, covering the potential of mycelium as a healthy building material, examples of biophilic design that are truly sustainable and biomimicry as a leading light in the new field of biodesign.

the potential of mycelium as a healthy building material / examples of biophilic design that are truly sustainable / biomimicry as a leading light in the new field of sustainable design

Welcome to episode 43 of the Green & Healthy Places podcast, brought to you by Biofilico healthy buildings & interiors.

In this episode I’m chatting to Danielle Trofe, a biodesigner with her own studio in New York who also lectures in biomimicry for The Pratt Institute and Parsons New School. Danielle is a part of the green building movement herald, promoting sustainable and biophilic design.

Danielle’s MushLume collection of lampshades made from organically grown mushroom mycelium and hemp have featured in the seriously cool, eco-luxury 1 Hotel Brooklyn Bridge amongst other projects and she is a leading proponent of biofabrication - that is using naturally grown materials in product design.

Our conversation covers all of these ‘bio’ terms that may understandably be new for many of you, we also look into the full Life Cycle impact of a design product from production through to end of life, we discuss how biophilic design can when delivered poorly equate to a largely superficial greenwashing of the interior design process, and we introduce the topic of green chemistry, that is research and development around new bio-based materials that designers such s Danielle can then introduce into future product development.

Conversation highlights

biophilic design allows us to connect to nature indoors, reminding us that we are still part of nature

a label of ‘nature-inspired’ doesn’t necessarily mean a product is good for both people and planet, poorly delivered examples of biophilic design may in fact be harmful to the environment

biomimicry as a movement is emerging as a rigorous framework for creating design that takes into consideration both our own health and that of the planet.

I think a lot of the biodesign field is really about taking action, it’s not just the study of it but rather how we can actually start making goods that help restore balance back to our ecosystems.

FULL TRANSCRIPT FOLLOWS COURTESY OF OTTER.AI (excuse typos)

Let’s begin with some terminology, specifically ‘biodesign’ and ‘biofabricated design’. How do you describe those two concepts to someone coming to this subject for the first time?

Danielle Trofe

In this past decade, or maybe even a little bit further, biodesign as a term has kind of come out in two different fields, one in the medical field and one in the design field. It’s serving a purpose as this catch all term that incorporates biomimicry, biofabricationbiophilic****design, to help those who don’t really know what each of those different facets really means. So that we can all kind of have the same conversation.

What is Biofabrication?

Biofabrication is what I do, it's about using a living organism to actually grow a product or design for you. So you're typically extracting something from nature or not, you can actually grow in a lab and and use that living organism to do the producing for you. In this case, I'm not not doing the manufacturing, the organism is actually doing that, for example mycelium - the roots of mushrooms - but also bacteria, algae or kombucha.

What is biophilic design?

I refer to Biophilic Design as the visual copying of nature and natural elements. We all have Biophilia, we all instinctively connect to nature in different ways, biophilic design is about tapping into that emotional state, that very native energy that we all have inside of us. Biophilic design has been shown to improve cognitive performance and provide health benefits. It allows us to connect to nature indoors, reminding us that we are still part of nature.

What is biomimicry?

Biomimicry goes a bit deeper by looking at Nature’s forms, processes and entire ecosystem, so it has these three different levels in other words. The aim is to draw out these principles to integrate them into human design to address any design or engineering challenge. Biomimicry involves understanding how nature overcomes similar challenges to the engineering challenge encountered. It leverages nature's evolutionary problem-solving to solve technological challenges.

Matt Morley

I think it’s very clear that you’ve mastered those concepts, it’s often so difficult to give a succinct description of concepts like biophilic design, yet you just managed to do it! Part of your work is in fact in education isn’t it? Besides being a designer you are also a teacher on biomimicry?

Danielle Trofe

Yes, correct. So I’ve been teaching biomimicry and biodesign at the Pratt Institute and the Parsons New School in Manhattan. I try to help orient students with an understanding of what this new field of nature inspired design is all about. That’s really what it is, it is a very new field, that is still unfolding, these terms are really being birthed at the moment, we continue experimenting with them.

Terminology can also vary from region to region. I know in the UK and in Germany, there are different terminologies for biomimicry for example. Everyone involved in this field is collectively trying to come up with a language to be able to talk about these particular topics such as biophilic design.

Matt Morley

There is so much discussion now around healthy buildings, healthy materials and wellness interior design on one side, with concerns over the sustainability of our buildings and interiors, the impact of our built environment on the planet, on the other. It looks to me like biodesign bridges those two worlds of wellness interiors and sustainable buildings.

It is not contributing waste, nor damaging the environment, and at the same time biodesign products are non-toxic, so these bio materials are inherently healthy and help contribute to an Indoor Environmental Quality plan.

Danielle Trofe

Yes… but with the caveat that it is done correctly! So let’s talk about that. Yeah, there is poorly delivered biomimicry, biofabrication or indeed biophilic design, right? You could create something that looks exactly like a tree. But if you’re using materials that can’t be recycled, that take tremendous amount of energy to create or that are mined unsustainably, you’re not really completing the holistic viewpoint of what biomimicry is, or hopefully in the larger sense, bio design.

My point is that just because it can fall under that label of nature-inspired, that doesn’t necessarily mean that a product is good for both people and the planet. The issue is that there’s nobody really there to judge what is or isn’t a high standard of biophilic design, for example.

So we’re kind of evolving together to be able to evaluate our own designs. Even if you are taking inspiration from nature, do you have the understanding and the tool set to be able to authentically factor in a products complete life cycle assessment, including where it’s coming from, how it’s affecting humans / nature during its use phase and the end of life disposal?

Whether that’s biophilic design, bio design, biofabrication or biomimicry, one thing that really stands out when you work in these fields is that there’s a greater framework for ensuring that a design meets all those needs throughout the process, from inception to production and end of life. This framework ensures that the number one thing and biomimicry is life can do, life creates conditions conducive to life.

That’s where I feel biomimicry as a movement is emerging as a more rigorous framework for creating design that really does take into consideration our health and the health of the planet.

Matt Morley

You’re practicing what you preach as you apply those same theories in your own products. And so that, in a sense leads us into the MushLume Biofabricated Lamps discussion. Why don’t we talk a little bit about how you have created a case study in a way of how to implement these ideas in a product-led business.

Biofabricated lamps

Danielle Trofe

Sure. Yeah, so about eight years ago, I started working with this amazing material that was coming out of upstate New York that was created by Ecovative - a mushroom mycelium material. And so for anyone who doesn't know what Mycelium is, it is the roots of a mushroom.

So just like an apple is the fruit of a tree. Mushroom is the fruiting body of this network of mycelia that live beneath the forest floor. And nature is the big recycler you know, it decomposes all dying and decaying matter in a forest or in an ecosystem. It connects all plants and an ecosystem actually is nature's communicator, it shares information, can warn other plants of impending danger, distributes water within a forest, shares nutrients underground… It really is this incredible organism that is one of the largest terrestrial organisms on the planet. There's one network that's known to be a couple 1000 years old in Oregon and stretches several football fields long.

Mycelium and hemp as healthy materials with positive health benefits

We take this mycelium and instead of extracting it out of nature, like we often do for most of our goods, we are we are inoculating it in a lab and reproducing it, then once it is in a liquid form we combine it with hemp and let nature do what it does best - grow! For that we put it in an environment that it wants to grow in, allowing the mycelium to bind to the hemp over a course of just a few days. You will see this white matte structure that actually solidifies all of the hemp.

The hemp is just used as support material for it to grow into, and also food as well. So cellulose, it wants to digest the cellulose. To give an understanding of the application of a lampshade, we create these forms, we pack them with the substrate that's already been inoculated. And then we just leave them to grow, we're not even adding additional water or energy into the production process!

Our largest lampshade, which is a 24 inch diameter dome takes about a week to grow. And if you think about this timeframe, to be able to use wood, you know, you're looking at anywhere from 25 to 100 years of a tree growing out in nature, and then you're harvesting this and you're putting all this energy into being able to process the material to use it.

We isolate mycelium in a lab, transport it a very short distance, and then let it grow in the course of just a few weeks. So you can already start to see the life cycle impact there.

The other most important part which is something that we're not as familiar with, but we're starting to understand its value now, is at the end of its life, the mycelium product is just going to decompose!

Biodegradable at end of life

Traditionally, in the last couple, maybe last 100 years, we've really wanted things to last. We want things to last as long as possible, we want them to be super durable. But we're starting to find out and especially since the invention of plastics that these might not be the best concepts. And rather than using materials that we're not quite sure how they're going to break down to an elemental form and affect our own bodies. We know exactly what's in these lampshades and they are going to actually add nutrients back into the soil rather than pollutants. So that's a completely different concept to a lot of our traditional goods.

And often people are like, Well, is it gonna break down in my living room but it's actually a very inert material. We do bake it at the end of its growth cycle, that's mainly to damage the cells enough so it won't continue to grow in your living room. It won't spore, it won't shoot off mushrooms. It's a completely stable, inert material in your living room. There's nothing that's going to break it down.

What's more the lampshades have this incredible soft feel, almost like a lamb's ear. So it's something that you actually want to touch. And there's not many lamps out there that inspire you to interact with it. And of course, that makes it a conversation piece, being able to talk with your guests at the dining room table about the light fixture that's overhead.

Matt Morley

You are rightly pointing out how long a lampshade really needs to be with us, where's that sweet spot between durability and being biodegradable. I wondered whether the lampshade had anything inherently suited to this particular medium. Could you have done any other number of things but you randomly selected the lampshade? Have you got an entire collection of products in your mind eventually?

Danielle Trofe

Yeah, so that's an excellent question. Part of the story is that Ecovative at the time was working mainly in packaging. So using the material to displace Styrofoam, which is a fantastic use for it.

We reached out to them, ordered samples and we wanted to start working with the idea of using it for a lampshade and it was kind of a crazy idea at that level eight years ago, and it ended up being one of the best use cases for it because of the material's properties. So to give everyone a better idea - when fully grown, it's very lightweight, it almost has the density of Styrofoam, but has a much softer exterior coat, which is actually the mycelium.

We can actually tune the material and kind of play with a little bit with its coloring. So yeah, we do have some that are not completely white. And that's the other thing about them. Once it's grown, the Mycelium is white, naturally. And that's how we leave them. So there's not any paint that's added to them. That's just the natural form that the mycelium takes.

Mycelium as an alternative to plastic packaging

It's great for packaging for single use packaging but it has limitations in terms of you a product like a chair or stool that is going to get bumped around, rubbed, scratched or knocked over. But for an object that's hanging above you suspended from the ceiling or perhaps a table lamp that's not always being touched, then that's a perfect case for using mycelium.

There were a number of years of us getting over shipping issues, modifying the form so that when they ship they don't crack or break, and they can be installed easily by the end consumer too. So there were huge learning curves of bringing this biotechnology to a place where you could commercialize a product.

I used to grow everything in Brooklyn, New York, I had a studio space here, and I would grow each one by hand. And just over this past year, year and a half, we move production to a company out in California who now grows all the lampshades for the studio. So we're able to finally expand past my own capabilities.

Biofabricated materials as a future trend

You're really seeing not just the general public, but the industry start to buy into Biodesign. Early on when we started to work with this material, nobody really knew what mycelium was, it was kind of a new term but the conversation has really shifted in the last five years so people know what Mycelium is.

There's all these startups around the world now working with mycelium whereas when I first started, there was maybe a handful around the world. We're talking single digits. So it's really been larger than just one studio or just a few companies. It's now so many young startups, working around biomaterials because they see the value in creating new products that are not going to necessarily pollute the planet or provide a negative impact.

Algae as a healthy material in design

Matt Morley

The other big player then, that I think deserves a mention in our conversation is algae - another biomaterial often mentioned in the same breath along with mycelium. Are you working with algae based materials too?

Danielle Trofe

Yeah, just when I started working with it, and it was for a completely different project, I ended up closing the studio to shift focus a little bit but we do work with it, for example an algae-based pigment to color the lampshades. We're collaborating with artists and designers to paint on our lampshades using algae ink. A start-up in Colorado has developed a new ink pigment derived from algae, which is fantastic.

There's also the Biodesign Challenge, which is a nonprofit organization that has a worldwide competition for young students to be able to create Biodesign applications and then have them be judged by professionals within the field. And there's been so many startups that have come from just these kinds of competitions, and you're really starting to see this field being driven by people that are under 30.

I really I do believe it's the generation underneath mine that is really going to power everything in terms of sustainability because they've inherited something that generations before did not - there has to be action. So I think a lot of the biodesign field is really about taking action, it's not just the study of it but rather how are we can actually start making goods that help restore balance back to our ecosystems.

Matt Morley

You collaborated with the 1 Hotel brand - they arguably reinvented what ‘eco luxury' could mean in hospitality. Can you talk to us about that project to help them create an example of biophilic design in one of their suites using your mycelium lampshades?

Biophilic design with natural elements in hotels

Danielle Trofe

Yeah it was fantastic. Working with 1 Hotel, that really was the project that elevated our lampshades to the next level, we did around 130 lampshades in this huge cloud in the presidential suite at the 1 Hotel Brooklyn Bridge. Biophilic design in hotels can support positive health benefits for guests.

Just working with 1 Hotel as a partner, it was really fantastic. We share the same values and be able to create different kinds of opportunities where the public can participate. So for instance, we had an exhibit where people could come in and see the lampshades being grown for the hotel. One of the things I realized is to hear the conversation that we’re having now, it’s really difficult to not physically see and feel the material, or watch the growing process. Demystifying that experience was really valuable.

The images that we got from that project really captured the possibilities of what our MushLume lampshades could do and have inspired a few other hotel installations since then too. We have grown from that as well I think, those images really did solidify that this is not just a case study. This is not just a single project but a commercialized product - that differentiation was huge. From there, we could move beyond this small niche to compete against big lighting brands, while also supporting positive health benefits through biophilic design in hotel suites.

Vertical gardens

Matt Morley

You've also got a vertical garden product that looks to be essentially a sort of an upright, vertically oriented planter for multiple plants. I'm wondering if you've got more things in the pipeline. Where do you go from here?

Danielle Trofe

Yeah, so the vertical garden was actually originally a hydroponic vertical garden. So that was the first product I ever created. And we launched that back in 2012. And it really kind of grew into a couple of installations with BMW.

The vertical garden now exists in the Brooklyn Botanic Garden. So if you go to their Visitor Center, you can see it there. And it's something that hasn't completely come to full realization, mainly because I started getting into the lighting and that kind of took off. But it's something I do want to bring back and one of the main reasons this was lagging is because at the time there weren't the tools to be able to create those planter pods. They look kind of look like Alien eggs, if you will.

So we created them out of thermoformed plastic which went against everything that I as a designer and as a studio believed in. So we've kind of been in this holding pattern to get to the right material and the right process to be able to recreate this. And that's actually being done right now, with much more sustainable materials.

For example we're looking at upcycling food waste into ceramic planter pods. So that's definitely something that's happening in the future. We hope to actually come out with a full product and not just an installation.

As for future, it's a good question. I recently became a mom. So a lot of things have really shifted. You know, even a fetus can contain over 100 Different manmade chemicals at that stage yet it's extremely difficult to find healthy materials or healthy interior products aimed at babies. That's the next thing I want to get into - green chemistry, and being able to actually bring products that are not toxic to our environments.

Green chemistry to develop new natural materials

Matt Morley

So the green chemistry thing for those who perhaps not clued up on it, that’s really where the nature-inspired R&D is taking place that then facilitates people such as yourself as a designer, to create the bio products you envision, that then are sold to bio-friendly businesses like 1 Hotels with their biophilic design in the bedrooms. Green chemistry is a crucial part of sustainable design, focusing on creating products that are environmentally friendly and efficient. It can help create products that mimic natural forms and patterns.

If you haven’t got the green chemistry, providing you with what you need - the tools and materials to create the products - then the products can’t materialize yet. These products can enhance human well-being and connection with the natural world.

Equally, if there isn’t also the consumer demand, the end market there to make it all into a viable business proposition, then the products either don’t materialize or remain prototypes and concept designs. So we have this delicate dance required to push the industry forward…

Danielle Trofe

Exactly - what you’re doing with the Green & Healthy Places podcast is also helping these fields to advance, by communicating these ideas to a wider public. We need to popularize the basics of what Biodesign is about, biomimicry, biophilia, all of the ‘bio whats’ to our industry and beyond, to consumers because ultimately consumers are driving the demand for these bio materials and bio products as well.

Clients are asking for things that are more sustainable. And they’re also starting to ask the questions. Well, where does this come from? How was it made? Hopefully ‘where does it end up?’ will be the next question that they’re going to ask…!

Danielle’s products are available in Europe through https://www.grown.bio/

Healthy Materials Lab at Parsons

The Parsons Healthy Materials Lab is all about placing health at the center of real estate architecture and design. They aim to raise awareness about toxics in building products and create educational online resources for designers and architects that further that cause.

This week we’re in New York talking to Jonsara Ruth, Co-Founder & Design Director of the Healthy Materials Lab and Associate Professor at Parsons School of Design.

Jonsara received a Masters of Architecture from Cranbrook Academy of Art and a BFA in Industrial Design from Rhode Island School of Design, she also has her own healthy materials design collective called Salty Labs.

The Healthy Materials Lab is all about placing health at the center of real estate architecture and design. They aim to raise awareness about toxics in building products and create educational online resources for designers and architects that further that cause.

I recently completed their 4-part Online Certification Program to become a Healthy Materials Advocate and cannot recommend the course enough, whether you work in this industry or are simply curious to understand more about buildings and the materials that go into them, both good and bad.

It’s far easier not to look under the hood, right? To trust that developers, architects and contractors have our best interests at heart… I hate to burst your bubble but that just ain’t so, nowhere is this more acute than in our homes, offices and Jonsara explains, the worst offender of all, the affordable housing sector.

Jonsara speaks with the precision of a Professor and the conviction of someone with a very clear mission in life, so listen up people, this is a good one.

If you enjoy this episode, hit like or subscribe for next week’s release.

See our 9-point guide to healthy buildings here.

CONVERSATION HIGHLIGHTS

Our central objective really is to remove harmful chemicals from the built environment that are prohibiting people from living healthy lives.

Just a few thousand years back People were building shelter exclusively out of what was around them - natural materials like wood from trees, clay, stone or water.